WP Bladder Forks

|

|

|

|

CARTRIDGE ASSEMBLY

CA1- Once the valving is complete, begin assembling the cartridge by inserting the completed damping rod assembly into the cartridge.

|

|

|

CA2- Line up the end of the damping rod with the seal. Use a 10mm t-handle on the top end of the damping rod. Do not attempt to "screw" it in. Give it a sharp rap with the heel of your hand to push the bottom end of the damping rod through the seal.

|

|

|

CA3- Fill the cartridge with USF-05 oil.

|

|

|

CA4- Bleed the cartridge by slowly compressing and then extending it. Make sure the compression stroke is slow or it will cavitate and create more bubbles.

|

|

|

CA5- Pressurize the bladder with only enough pressure to make the bladder taught (it's normal shape). This will be less than 1 psi.

Another method of returning the bladder to its normal shape is to pinch the bladder at the cap. This will make a small opening in the sealing surface and allows air to enter. If it does not look "taught" you will need to pressurize it with a needle.

Insert the Compression/Bladder Assembly into the end of the cartridge. Be sure there is enough oil so that the cartridge overflows.

|

|

|

CA6- Tighten the Compression/Bladder Assembly with a Fork Cap Wrench (TFCW 50H). As it is screwed in, the bladder will compress slightly. Don't worry the next step will restore it to its original shape.

|

|

|

CA7- Hold the Cartridge in a vise as shown with the cartridge slightly angled so the Bleed Screw is at the highest spot.

Remove the bleed screw. This will release any trapped air and allow the bladder to expand to it's original state. A bit more oil will dribble out.

|

|

|

CA8- Reinstall the bleed screw.

|

|

|

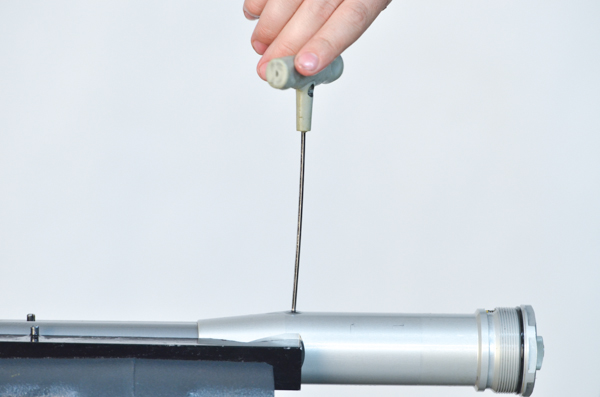

CA9- With the cover screw out insert the Nitrogen Needle (TSNN 01) and...

|

|

|

CA10- Pressurize to factory recommended setting. Usually this is about 17.5 psi.

|

|

|

CA11- Reinstall the Nitrogen Cover Screw.

|

|

|

CA12- Install the Compression Adjusting Knob.

|

|

|

CA13- Install the flat head screw.

|

|

|

CA14- Put the Jam nut on the end of the damping rod.

Check for proper assembly by compressing the fork and allowing it to extend. It should extend all the way. If it does not you may have a damaged damping rod or too little oil or pressure.

|

|

|

CA15- TA-DAAAAA!!!!

The rest is basically the same as most other Twin Chamber forks.

|

With the switch to the new racetech website and systems we are requesting each user reset their password in our system. Simply use our forgot password feature on the login page to reset yours.