FORK SPRING PRELOAD - INTERNAL TOP-OUT SPRING

|

|

|

|

These instructions are made using an Upside-Down WP 4CS fork. This one is a little tricky because the spring rests up inside the cap. Everything else is the same for both Right-Side-Up (conventional) and Upside-down forks.

1- Back out any damping and/or Preload Adjusters on the fork cap all the way.

This step is in preparation for reassembly so the adjuster is not damaged.

|

|

|

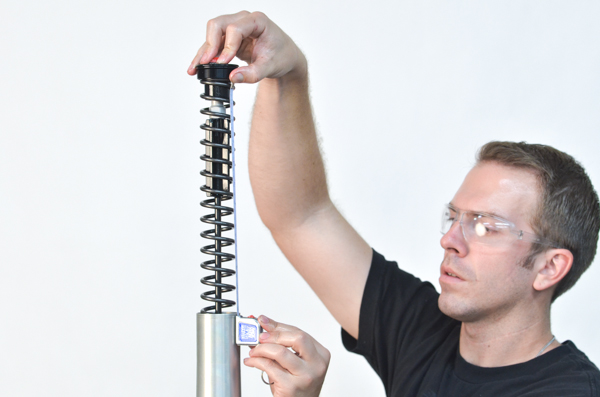

2- Unscrew the fork cap.

For the WP 4CS fork we have a really cool Fork Cap/Comp Assembly Tool (TFCW PS3648) available.

|

|

|

|

|

|

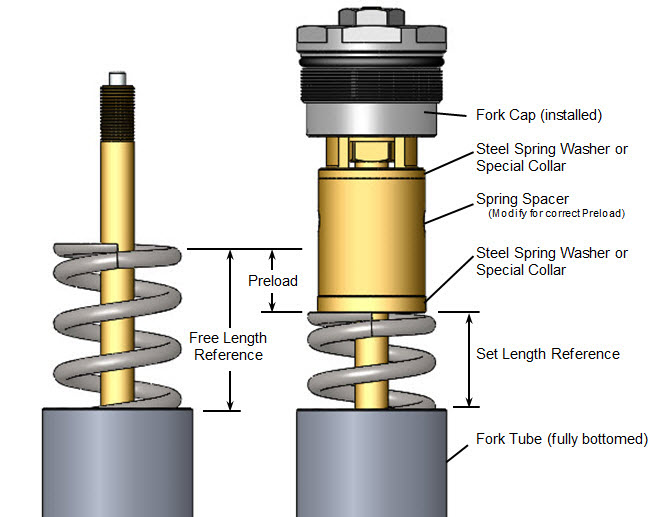

4- Insert the new spring.

Bottom the Outer Fork Tube fully (the Inner Chrome Tube on a Conventional Fork.)

Measure from the top of the Spring to the top of the Fork Tube.

This is the Free Length Reference.

|

|

|

5- Find out where the fork spring touches the cap. On some models the spring fits into a recess. On the WP 4CS it is 7mm deep. There are many styles; some with preload adjustment, some that require a spacer or tube. The cap is NOT recessed on many models. |

|

|

6- Install the cap fully onto the rod. Preload adjuster backed out all the way applicable.

Measure from the top of the Outer Fork Tube to the top of the Spring. This is the Set Length Reference. The difference between the two measurements is the Preload.

The Free Length minus the Set Length is the Preload. For 4CS forks measure to the bottom of the Cap and add 7 mm for the recess depth. Make sure there is positive preload. In other words the Set Length is less than the Free Length.

|

|

|

7- Set the Preload

See the Product Search or your DVS Setup Sheet for Preload recommendations.

Adjust the preload by adding or subtracting washers or adjusting the Preload Spacer Length.

The spring should always rest on a steel or plastic washer. It should NEVER rest on the aluminum fork cap. Be sure to take washer thickness into consideration.

On many Open-chamber forks washers are added at the bottom of the spring.

The Preload Washers must be centered. They cannot be allowed to shift sideways on an Upside-down fork or they may damage the fork tube.

|

|

|

|

|

|

9- Set the adjusters to the recommended settings.

Put on the cool Race Tech fork stickers and have fun!

|

With the switch to the new racetech website and systems we are requesting each user reset their password in our system. Simply use our forgot password feature on the login page to reset yours.