2.7.3 Husqvarna 35 & 40mmCR/WR 1975-87Customer Install - Not RT Only | ||

Stock Rods - this shows both sides (only the top hole goes through) | 1975-87 - Customer install - Not RT Only Click here for an explanation of how and why we do this mod. These fork mods are much simpler than 1972-74. They have hydraulic top-out and bottom-out. They do not have top-out springs. | |

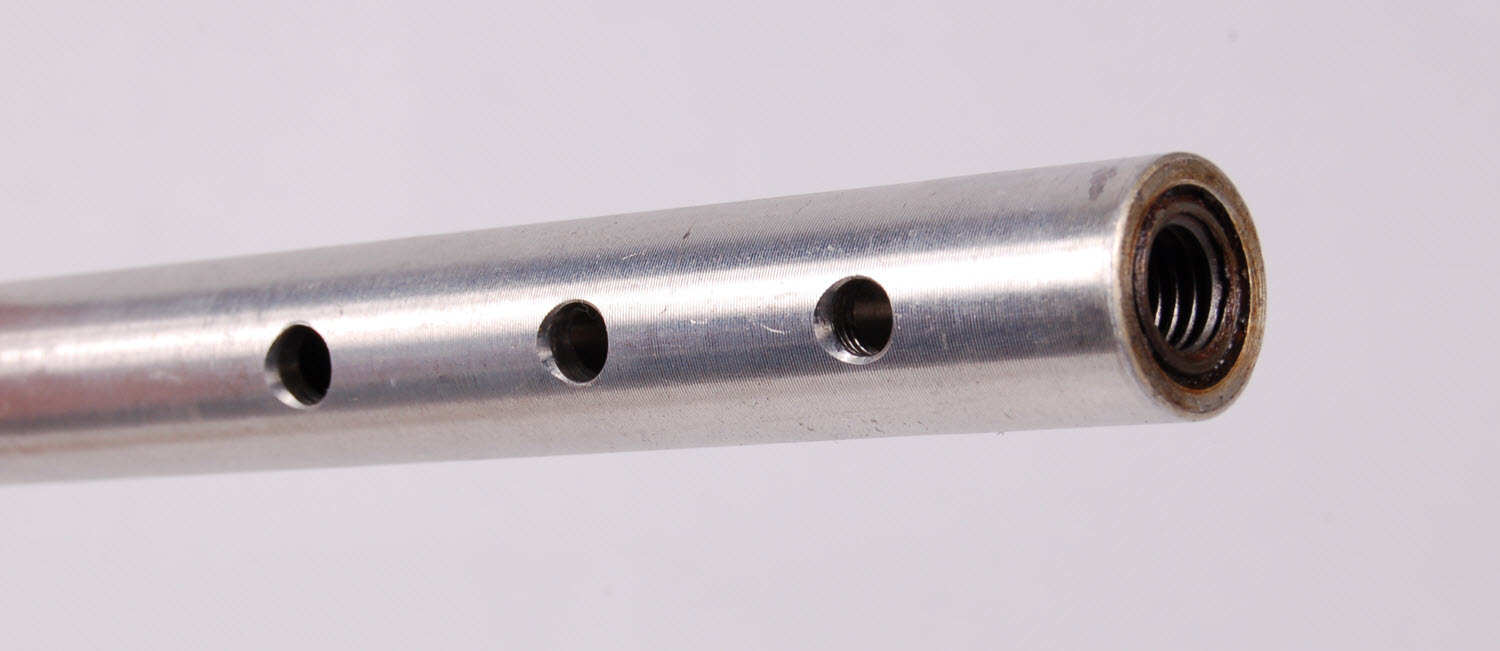

| 40mm - ENLARGE THE COMPRESSION FEED HOLES 40mm Damping Rods Drill the existing 8mm (middle) hole through. Add one set of holes half way between the top holes and the second ones down at 90 degrees to the originals. There will be 7 holes total. Deburr inside and out. Do not modify the lower hole. The rod is tapered there for hydraulic bottoming resistance. The stock rod is the top image. Modified on the bottom. | ||

| 35mm - ENLARGE THE COMPRESSION FEED HOLES 35mm Damping Rods These are pictures of the stock 35mm Rods. The top two images are flip sides of the same rod. Just like the 40mm rod only one hole goes all the way through. Drill so the top two sets of holes go through. Match the original hole size or use a 6mm (1/4") drill. Add 2 more holes midway between the top two bores at 90 degrees to the originals. This is similar to the mod on the 40mm rods. There will be 7 holes total. Deburr inside and out. Leave the bottom hole alone and do not drill it through. | ||

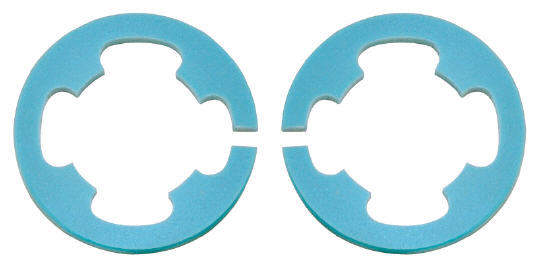

| REPLACE THE PISTON RINGS 1975 and later forks have plastic Piston Rings. When working properly, these piston rings fill the rebound chamber adequately. However, it is common for the stock Piston Rings to be worn out or broken. RT makes replacement piston rings from a PTFE material. It is both long lasting and more slippery than stock. These are FPPR HQ35 or FPPR HQ40 piston rings. | |

| SURFACE THE TOP OF THE HEAD It is common for the fork spring to wear a step in the top of the head. Machine or carefully file this off flat so the Adapter seals. This picture shows the stock wear pattern. By the way, the aluminum that wears off ends up in the oil. This is a design flaw that is eliminated with an Emulator. | ||

The stock hardware is pretty interesting. From left to right:

We recommend using a FMCW 0813 copper washer on the bolt for ease of sealing. This is not required. | ||

See Standard Emulator Instructions.for direction on fork spring preload and oil level.

| ||